Image 4 began as a photo print lab, back when the only way to present large-scale images and communications was to use enlargers and chemicals. 35 years and thousands of projects later, we still use the same quality-control methods to manage color and image quality. Our print quality is second to no one in North America and it shows in your wallcoverings, glass marking and murals.

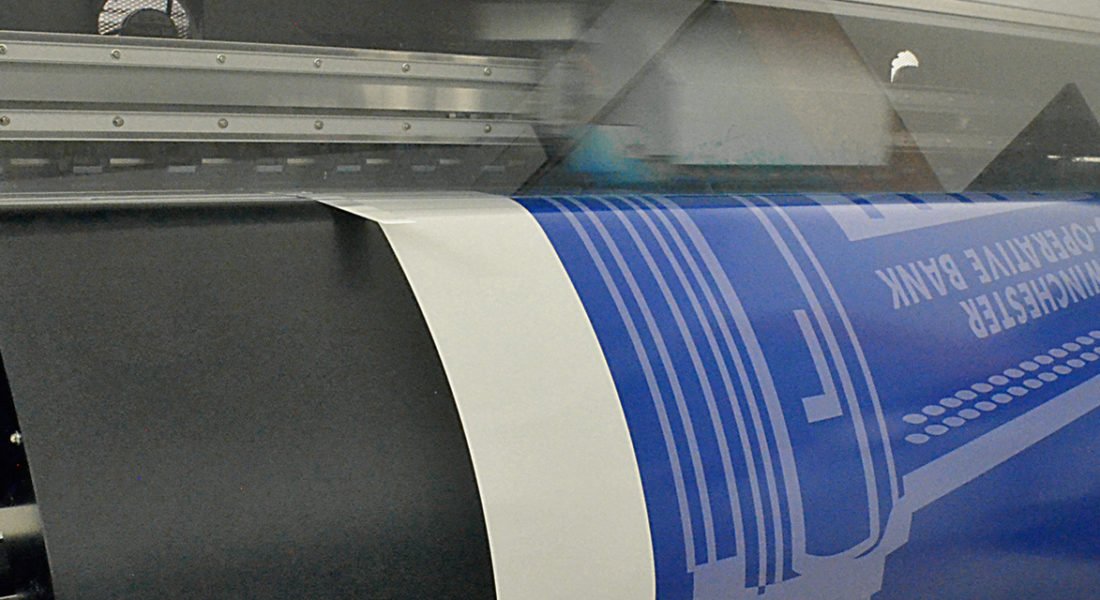

Today, our extensive digital print studio prints on “best-in-class” roll-to-roll and flatbed print machines, driven with industry leading software through custom color-management systems.

Our Print Studio includes:

- Onyx ProductionHouse RIP and Production Management Platform: Onyx makes the most robust, versatile and accurate production integration backbone in the print industry. Our integrated-backbone architecture allows us to onboard art and CAD files, process them, apply color management and drive them to any of our printers and substrates in a closed-loop environment. Graphic files can be integrated with fabrication files from your workflow or ours, assuring you that dimensions and color targets will be as specified.

- Epson S80-600: This high-speed, 12-color printer features variable dot screening to deliver amazing image quality on a variety of substrates. Impossible colors can now be accurately matched, thanks to its 12-color inkset.

- Seiko ColorPainter M64S: This extremely high-speed printer is a production workhorse, used primarily for banners and wallcovering. The color quality is fantastic and the throughput is crazy, helping keep prices low.

- HP 570 Latex: Latex printing does not off-gas, so it’s a perfect solution for LEED projects and healthcare environments. Our 570 delivers beautiful images on fabrics, polyester, fiber-based wallcoverings, transparency film and other roll materials at a very high throughput.

- OCE Arizona 360GT: We’re thrilled to print with the highest resolution, fastest (at resolution) flatbed printer available. The 360GT’s 2-picoliter variable dot head allows us to deliver incomparable print quality and color fidelity on rigid materials – PVC, acrylic, metals, glass and wood. Combined with a best-in-class ink permanence, the OCE is a fantastic tool to deliver architectural installation and signage graphics and images.

- Summa D2 Cutter: Again, the fastest roll cutter available, our 64” D2 cuts films and graphics off rolls at a speed that honestly can be scary! From logos and lettering to glass application and marking, our D2 converts your art elements into 2-D shapes for application throughout projects. Even better, the Summa D2 is CAM integrated via our RIP software to all three roll printers. This means what we print, we can cut with a 3-decimal degree of accuracy.

- Techno 59120 Drag Cutter/Router: Release the Beast! Sporting a 3D, 7.5HP multi-spindle cutting head and a 2D 600gram drag cutter, our 5×10-foot router table is CAM-integrated with our OCE Arizona. What we print we can cut in 2 and 3 planes, to a 3-digit degree of accuracy. From styrene and PVC to Plyboo to .063 aluminum and even 3” 3030 billet Aluminum, the Techno is our daily problem-solver.

- Quality Control: Image 4 operates under a highly-developed Quality Management System that has been validated multiple times by Tier-1 and Tier-2 manufacturers. QMS begins with incoming-materials QC inspection and flows through the entire production stream – touching every transfer point and check point. Our closed-loop color management system extends to color-controlled lighting throughout our plant, color-correct and calibrated monitors, and individual substrate LUTS that are generated in-house. All of this assures our clients that the color they specified will be the color that is delivered. We’ve never forgotten that Image is in our name.